HTML

Commentary - (2022) Volume 12, Issue 2

Manufacturing of MRNA Drugs: Current Situation and Future Prospects

Bramara Malini**Correspondence: Bramara Malini, Department of Pharmacy, National University in Taipei, Taipei, Taiwan, Email:

Received: 07-Feb-2022, Manuscript No. IJP-22-60661; Editor assigned: 11-Feb-2022, Pre QC No. IJP-22- 60661(PQ); Reviewed: 21-Feb-2022, QC No. IJP-22-60661; Revised: 28-Feb-2022, Manuscript No. IJP-22- 60661(R); Published: 07-Mar-2022, DOI: 10.37532/2249-1848-22.12.06

Description

The COVID-19 pandemic has moved mRNA (mRNA) vaccines from a niche technology into the mainstream, with hundreds of millions of doses delivered. Companies like Moderna, BioNTech, and CureVac may pivot their mRNA initiatives for cancer vaccines, protein replacement therapies, and other vaccines to respond quickly to the threat of SARS-CoV-2 because of the modular nature of mRNA.

This is because, unlike small molecules and protein-based medicinal agents, mRNA may be tailored to transcribe almost any protein while retaining almost identical chemical properties. Nucleoside modifications, Lipid Nanoparticle (LNP) compositions, and manufacturing can now be kept substantially unchanged. Since 2012, preclinical proof-of-concept research has proven that mRNA is ideally suited for speedy pandemic response, and the COVID-19 pandemic has underlined the urgent need to commercialise these technologies.

The modularity of mRNA and its widespread acceptance have accelerated the clinical and preclinical development of new mRNAbased vaccines and treatments. This intensification will boost demand for RNA Drug Substance (DS) and LNP formed Drug Product (DP) manufacturing, which is already strained due to global demand for SARS-CoV-2 vaccines. Shortages or delays in receiving ordered doses have occurred outside of the United States and Europe due to production problems.

The modularity of mRNA and its widespread acceptance have accelerated the clinical and preclinical development of new mRNA based vaccines and treatments. This intensification will boost -demand for RNA Drug Substance (DS) and LNP formed Drug Product (DP) manufacturing, which is already strained due to global demand for SARS-CoV-2 vaccines. Shortages or delays in receiving ordered doses have occurred outside of the United States and Europe due to production problems.

We also look at current RNA DS and LNP DP manufacturing technologies to see where they could go in the future. Finally, we look at developing manufacturing methods and trends in RNA treatments to get a sense of where the area is headed in the future.

Because RNA medicines are modular, they can be quickly adapted to generate vaccines to prevent the COVID-19 pandemic. As vaccination discoveries are utilised to speed the development of other RNA-enabled gene and cell therapies, this modularity will also bring about the RNA revolution in the biopharmaceutical industry. In 2021, the number of publications and clinical trial registrations increased dramatically, increasing demand for RNA DS and LNP DP manufacturing, which was already stretched to meet worldwide demand for SARS-CoV-2 vaccines. These, and future industrial constraints, present opportunity for new technologies and advances.

Technologies like saRNA reduce dosing by up to 100-fold, allowing existing infrastructure to improve its manufacturing capacity while also allowing new equipment to be created at smaller sizes. In contrast to the present fragmented strategy that requires the shipment of bulk intermediates between states and nations, smaller-scale production allows for the integration of DP manufacture, DS formulation, and fill/finish activities into an unified suite.

Additionally, commercially available next-generation mixers have recently been launched, allowing throughput from a single mixer to be scaled to suit all stages of drug development. Microfluidic technology, which has already been established for preclinical development of RNA-LNPs, has recently seen the launch of commercially available next-generation mixers.

The tendency in integrating production stages coincides with announcements by a number of governments to build domestic RNA medication manufacturing capacity in response to SARS-CoV-2 vaccine shortages in a few jurisdictions. In pandemic conditions, these facilities can generate the medications that the local population requires, as well as vaccinations that target regional varieties. A multiproduct manufacturing paradigm, in which sequences for multiple RNA DSs for gene silencing, protein replacement, vaccinations, and RNA designed cell treatments are saved digitally and created on demand, can achieve economies of scale from these smaller facilities. A methodology like this might also improve the economics of developing therapeutics for uncommon diseases, paving the way for genuinely personalised RNA treatments in the future.

Manuscript Submission

Submit your manuscript at Online Submission System

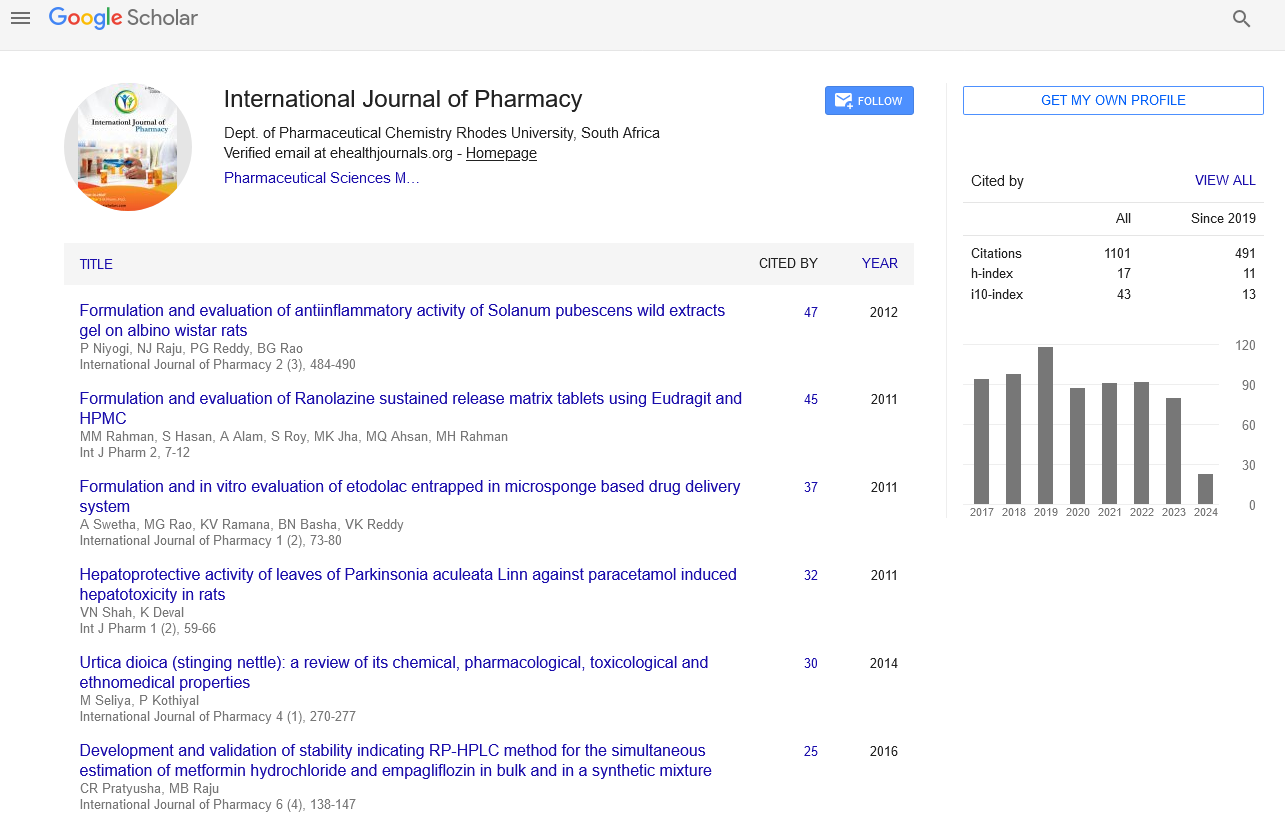

Google scholar citation report

Citations : 1101

International Journal of Pharmacy received 1101 citations as per google scholar report

International Journal of Pharmacy peer review process verified at publons

Indexed In

- CAS Source Index (CASSI)

- HINARI

- Index Copernicus

- Google Scholar

- The Global Impact Factor (GIF)

- Polish Scholarly Bibliography (PBN)

- Cosmos IF

- Open Academic Journals Index (OAJI)

- Directory of Research Journal Indexing (DRJI)

- EBSCO A-Z

- OCLC- WorldCat

- MIAR

- International committee of medical journals editors (ICMJE)

- Scientific Indexing Services (SIS)

- Scientific Journal Impact Factor (SJIF)

- Euro Pub

- Eurasian Scientific Journal Index

- Root indexing

- International Institute of Organized Research

- InfoBase Index

- International Innovative Journal Impact Factor

- J-Gate