Abstract

MULTIPLE UNIT PELLET SYSTEMS: A REVIEW

VR Sirisha K, K Vijaya sri, K Suresh and G Kamalakar Reddy

Compressed multiple unit pellet tablets/multiple unit particulate or pellet system commonly called MUPS are composed of polymer coated subunits namely pellets; which are embedded in an inert excipients matrix designed to overcome the difficulties in administering capsules and improved physico-chemical stability compared to suspensions. The functional coating like drug coating, barrier coating, enteric polymer coating is usually applied in a fluid bed coating processor provides each subunit with the characteristic desired drug release properties. The size, shape and surface morphology of the pellets to be coated are the prerequisites for coating of pellets. Design of MUPS involves formulating pellets by different techniques and further compression of these pellets into rapidly disintegrating tablets; disintegrate rapidly in the oral cavity for the delivery of coated pellets into the gastrointestinal tract or the site of release of the drug. Inspite of the challenges like content uniformity of the compressed tablets, ability of the film to withstand compression force; MUPS occupy a prominent role in formulating drugs due to their greater patient compliance; process, formulation and therapeutic advantages.

Manuscript Submission

Submit your manuscript at Online Submission System

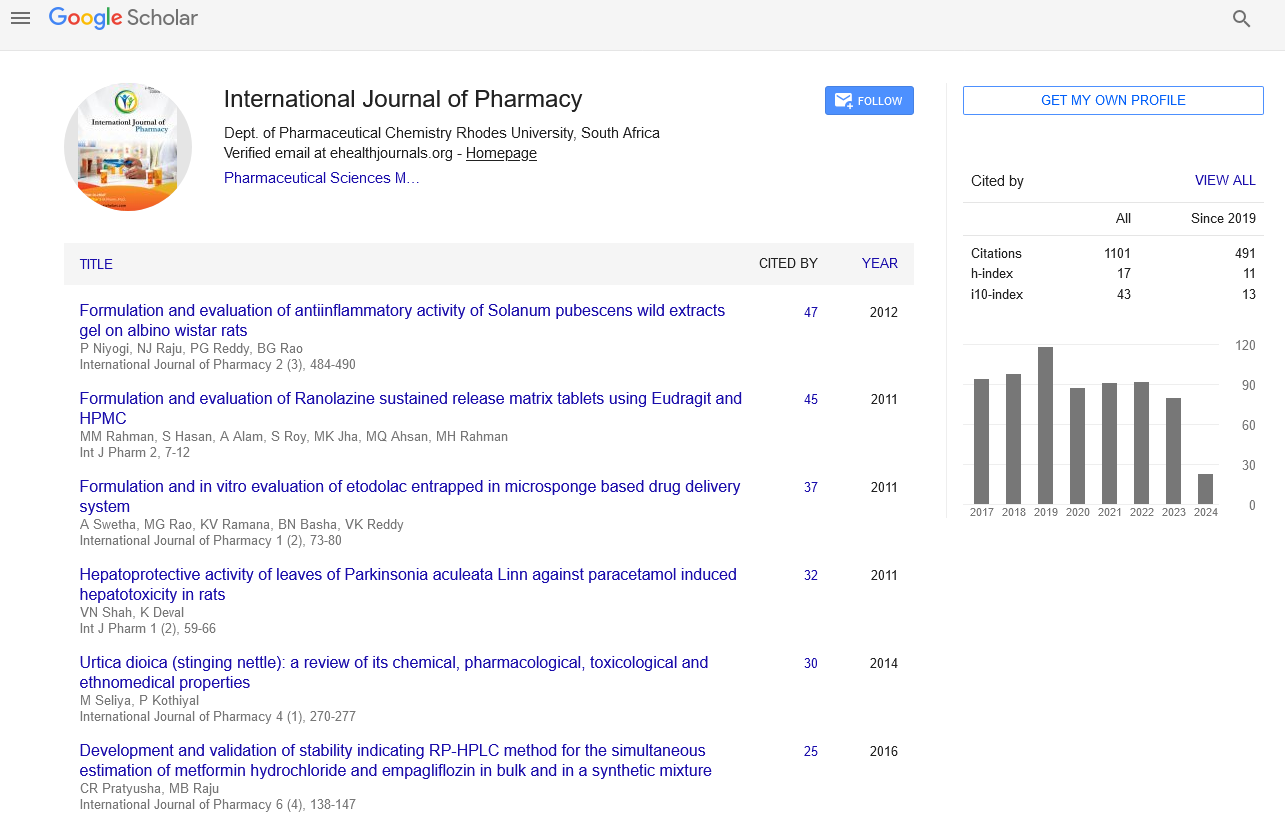

Google scholar citation report

Citations : 1101

International Journal of Pharmacy received 1101 citations as per google scholar report

International Journal of Pharmacy peer review process verified at publons

Indexed In

- CAS Source Index (CASSI)

- HINARI

- Index Copernicus

- Google Scholar

- The Global Impact Factor (GIF)

- Polish Scholarly Bibliography (PBN)

- Cosmos IF

- Open Academic Journals Index (OAJI)

- Directory of Research Journal Indexing (DRJI)

- EBSCO A-Z

- OCLC- WorldCat

- MIAR

- International committee of medical journals editors (ICMJE)

- Scientific Indexing Services (SIS)

- Scientific Journal Impact Factor (SJIF)

- Euro Pub

- Eurasian Scientific Journal Index

- Root indexing

- International Institute of Organized Research

- InfoBase Index

- International Innovative Journal Impact Factor

- J-Gate